ID FANS (BLOWERS)

ID FANS (BLOWERS)

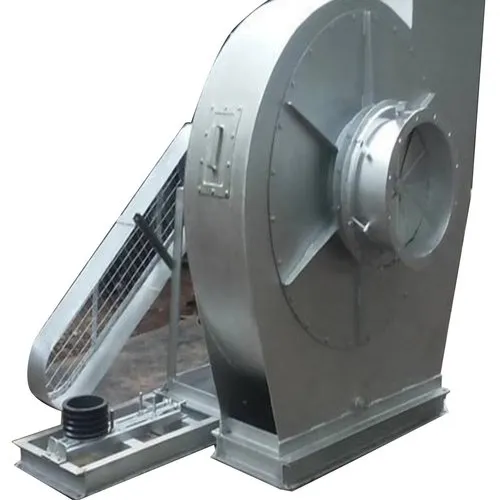

Supreme Plastic is a leading manufacturer of high-performance ID (Induced Draft) fans, providing innovative ventilation solutions for a wide range of industries. Our ID fans are designed to deliver superior performance, efficiency, and reliability, ensuring optimal air quality and system functionality. With a focus on quality and customer satisfaction, Supreme Plastic is your trusted partner for all your industrial ventilation needs.

Induced Draft (ID) fans are essential components in industrial processes, offering significant benefits such as enhanced efficiency, improved safety, and versatile application. These fans ensure optimal airflow management, leading to energy savings and reliable performance, which minimizes downtime and operational costs.

They play a critical role in emissions control and temperature regulation, contributing to a safer work environment by reducing the concentration of harmful fumes and gases. Additionally, ID fans are highly versatile, suitable for various industrial applications, and customizable to meet specific operational requirements. By investing in high-quality ID fans, industries can achieve better operational efficiency, compliance with environmental regulations, and a safer workplace.

DETAILS

| Specifications | Details |

|---|---|

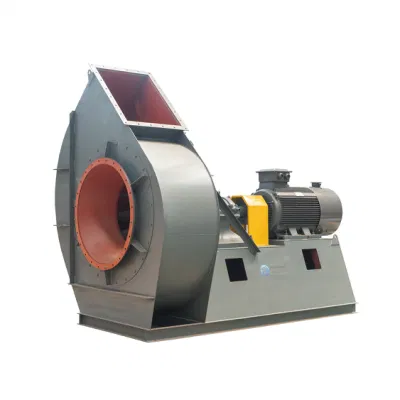

| Material Composition | – Constructed from high-quality materials such as stainless steel, carbon steel, and specialized alloys. Designed to withstand high temperatures and corrosive environments. Coatings and treatments available for enhanced durability and longevity. |

| Capacity Range | – Available in a wide range of capacities to meet various industrial needs.<br>- Flow rates can range from 1,000 to over 100,000 cubic feet per minute (CFM). Customizable sizes and configurations to match specific application requirements. |

| Design and Construction | – Engineered to comply with industry standards and safety regulations. Aerodynamic design to maximize efficiency and reduce energy consumption.- Features include variable speed drives, noise reduction mechanisms, and vibration control. |

| Applications | Details |

|---|---|

| Power Plants | – Used for removing exhaust gases from boilers and ensuring optimal combustion. Essential for maintaining efficiency and reducing emissions. Applicable in both thermal and nuclear power plants. |

| Manufacturing Facilities | – Provides ventilation and controls air quality in industrial processes.- Removes dust, fumes, and excess heat from production areas. Suitable for industries such as cement, steel, and glass manufacturing. |

| Chemical Processing | – Critical for maintaining safe and controlled environments in chemical plants.- Used in processes involving volatile and hazardous substances. Helps in managing emissions and improving worker safety. |

| Advantages | Details |

|---|---|

| Enhanced Efficiency | – Optimized for consistent and efficient airflow management. High efficiency leads to significant energy savings and reduced operational costs.- Reliable performance minimizes downtime and maintenance needs. |

Connect With Us

At SUPREM PLASTIC FABRICATORS, we are committed to providing you with the best products and services to meet your specific needs. Our team of experts is here to assist you with any inquiries or requirements you may have