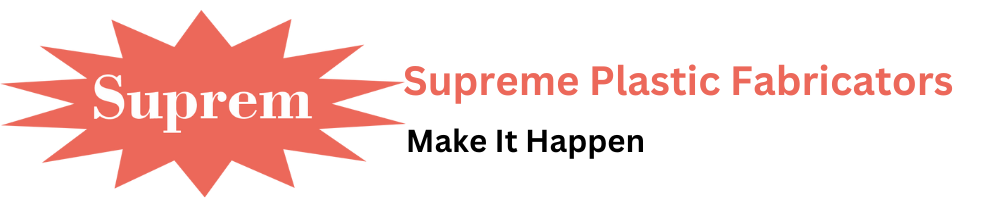

PRESSURE VESSEL

PRESSURE VESSEL

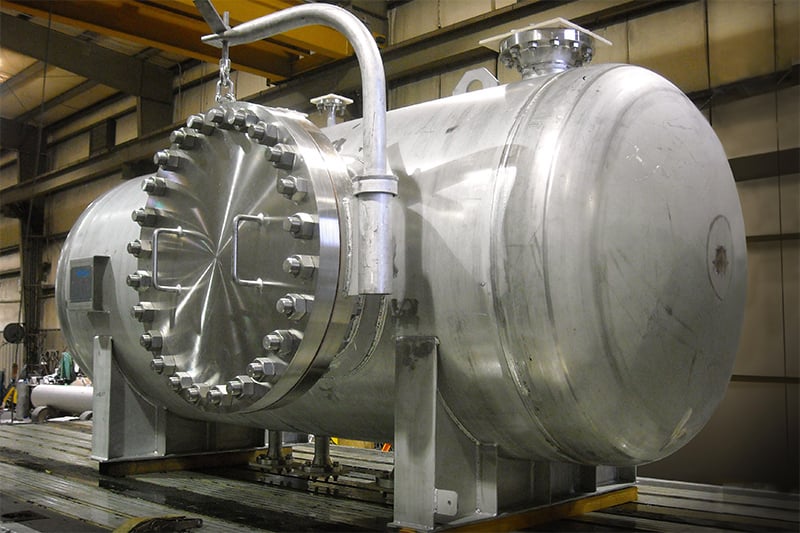

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. These vessels are crucial in various industries for storing, processing, and transporting substances under high pressure or temperature conditions safely and efficiently. They are built to withstand the internal pressure exerted by the contents without any leakage or deformation.

Pressure vessels play a critical role in modern industrial processes, ensuring the safe handling of fluids and gases under high-pressure conditions while contributing to operational efficiency and reliability across various sectors. Their design and fabrication adhere to stringent standards to guarantee operational safety, environmental compliance, and long-term performance in diverse industrial applications.

DETAILS

| Specifications | Details |

|---|---|

| Material of Construction | Constructed from materials like FRV, PPH+FRV, CPVC+FRV, PVDF+FRV. |

| Design Standards | – Fabricated according to international standards such as ASME BPVC, PED, and national regulations. Ensures compliance with safety codes and regulations for pressure containment. Includes design features for safety, maintenance, and inspection requirements. |

| Types and Configurations | Various types include storage tanks, reactors, Dosing tank and Self Priming Pot. Configured to meet specific industrial process needs and operating conditions. Customizable designs for different applications and environmental conditions. |

| Applications | Details |

|---|---|

| Chemical Industry | – Used for storing and processing chemicals under controlled conditions. Ensures safety and efficiency in chemical reactions and production processes. Handles corrosive substances and volatile chemicals with appropriate material selection. |

| Oil and Gas | – Essential for storing and transporting petroleum products and natural gas. Utilized in refineries, pipelines, and offshore platforms. Ensures safe containment under high-pressure conditions in exploration and production operations. |

| Food and Beverage | – Used in food processing and beverage production for sterilization and pasteurization. Stores liquids under pressure to maintain product quality and safety. Ensures hygienic handling and preservation of food and beverage products. |

| Advantages | Details |

|---|---|

| Safety | – Designed with safety features such as pressure relief valves and robust construction. Prevents leaks or failures under high-pressure conditions. Ensures operational safety for personnel and equipment. |

| Efficiency | – Maintains stable pressure and temperature conditions, optimizing production processes. Enhances energy efficiency and reduces operational costs. Supports continuous operation and minimizes downtime. |

| Durability | – Built to withstand harsh environments and prolonged use. Minimizes maintenance and replacement costs over the vessel’s lifespan. Provides long-term reliability and performance in industrial applications. |

Connect With Us

At SUPREM PLASTIC FABRICATORS, we are committed to providing you with the best products and services to meet your specific needs. Our team of experts is here to assist you with any inquiries or requirements you may have